Fasten drip edge on eaves with galvanized nails and a hammer about 12 inches apart before laying roof felt.

Rolled roof felt nailing pattern.

Contact roofhelp 9 18 nailing pattern for roofing felt each row of nails that are 18 on center should be approximately 12 from the outside edge of the roll.

The roofing should overhang the eaves by inch except where you install drip edge flashing on top of the roofing along the rake edge.

Setting the roll and then nailing off.

Starting a roof with tarpaper felt.

Installing the roofing felt does take care but can go very quickly.

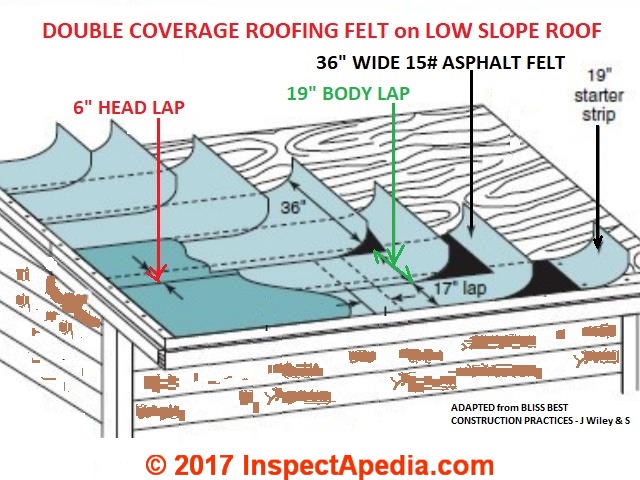

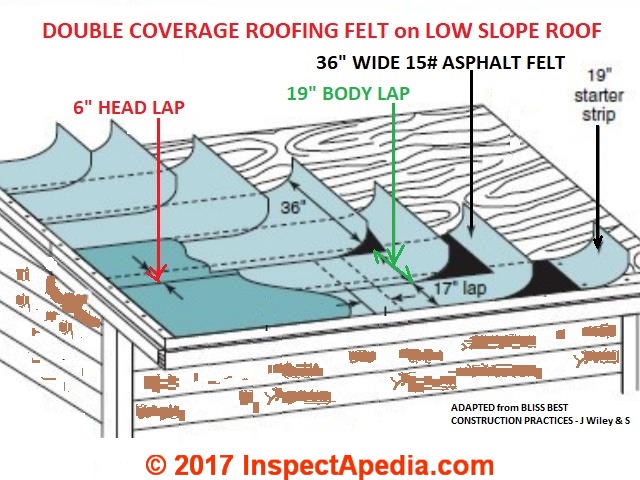

Cover the preceding layer with 36 inch roll roofing.

The top edge of the felt should be nailed no less than every eight inches.

From behind the roll reach over and nail down the top of the strip with roofing nails spaced 6 to 8 inches apart.

Pull straighten and align the felt along the eaves.

This video walks through the very basic steps for installing tarpaper felt.

Be sure that there are no wrinkles.

However there are other advantages to roll roofing including that it can last up to 12 years.

Tear out the sheathing that is emerging out of the valley.

Contact roofhelp 12 24 nailing pattern for roofing felt each row of nails that are 24 on center should be approximately 12 from the outside edge of the roll.

These thick layers of roofing felt are installed by heating the back of the felt with a butane torch and then carefully applying it to the roof.

Some roofing felts are actually glued down.

An underlayment of felt roofing is optional.

Nail the middle and bottom of the felt similarly.

Defer putting drip edge on angled gable ends until after the felt is laid so the metal.

Roll out the felt toward the other end of the roof.

The nails should start 3.

Hammer down the nails at the edges of the sheets covering the valley.

Pick up the roll with both hands.

Anchor the top corner of the felt after it has been properly positioned and roll the felt out across the roof.

Nail down the 18 inch roll roofing sheet that it is covering the valley.

You will need 1 10 gallon of lap not mastic cement for every roll and 2 pounds of roofing nails for every square.

These applications are ideal for flat roofs or protective surfaces under roof level decks.

This is why so many people choose roll roofing over other types of roofing material.