Un flatness leading to water carryover.

Roll defects in titanium sheet metal.

Gas tungsten arc welding gtaw also known as tungsten inert gas tig welding is an arc welding process that uses a non consumable tungsten electrode to produce the weld the weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas argon or helium and a filler metal is normally used though some welds known as autogenous welds or.

More importantly the tendency to springback decreases especially in comparison through the one observed in the v die bending tests.

This is article is part 1 of a four part series covering flatness and stability in cut to length slitting and tension leveling operations.

It is shown that there are significant differences in shape defects in the industrial roll forming of a particular channel section depending on whether the strip is fed in with the convex side upwards or downwards.

Satin nick elliptical aluminum sheet model 57010 18 98 18 98.

M d building products 1 ft.

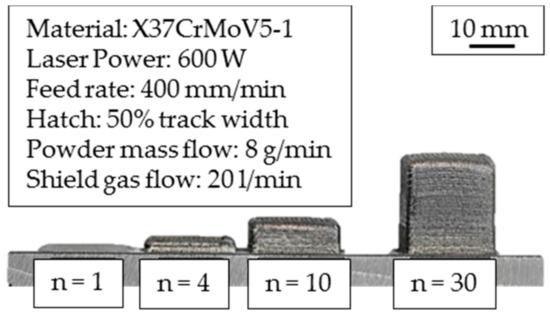

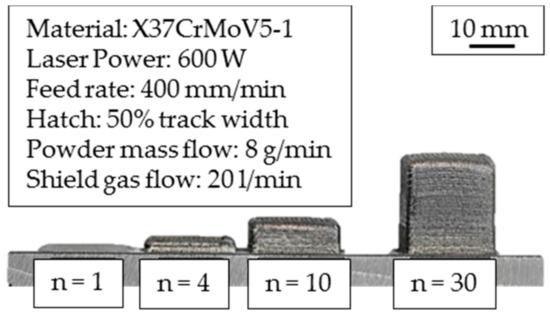

Roll forming reduces the risk of structural defects representing a potential solution for titanium sheet forming at room temperature.

The roll forming of two coils exhibiting coil set is studied.

This article covers how flat rolled metal gets unflattened including the 3 categories of defects how defects are created at hot and cold mills and how coil processors also create defects.

4 7 out of 5 stars 259.

Dust in roll 7 1 2 edge curl 4 0 2 scalloped edge 0 4 5 serrated edge 2 0 2 roll knots 1 0 8 the ultimate roll and web defect troubleshooting guide slitting and trim related defects 57 16 46 18 specific slitting defects 57 specific slitting causes 16 specific trim causes 46 other causes 18 254 roll web defects.

This process flattens pieces of metal ensures they re the right size.

However there are a few problems that can occur during rolling.

Many of these materials such as ti 6al 4v are superplastic without special processing.

Each coil has similar tensile and bending properties.

To make sure the sheet metal manufacturing process is smooth a rolling machine is used.

5 0 out of 5 stars 1.

22 gauge metal sheet model 801447 8 98 8 98.

Get it as soon as wed sep 30.

The formed sheet metal will adhere to rolled surface and to follow the path of their respective rolls sheet will shear in the plane and defect is called as alligatoring.

Fixturedisplays galvanized sheet metal roof roll siding metal fabricate metal 4ft wide 25ft long 11811 100sf.

The formability of the titanium alloy can be improved through roll forming.

However a number of titanium alloys especially the a b alloys exhibit superplastic behavior.

Set your store to see local availability add to cart.

Let s discuss potential sheet metal rolling defects causes and remedies.

The workhorse superplastic titanium alloy is ti 6al 4v and the state of the art in titanium superplastic forming is largely based on this alloy.

Free delivery with 45 order.