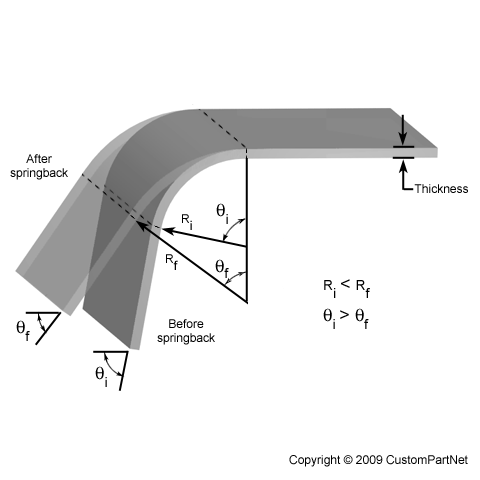

The plastic strain ratio r is considered a direct measure of sheet metal s drawability and is useful for evaluating materials intended for forming shapes by deep drawing see lead photo.

R value sheet metal forming.

In construction the r value is the measurement of a material s capacity to resist heat flowfrom one side to the other.

The r value is an index that the material can resist thinning deformation in thickness direction.

The r value is the ratio of the true strain in the width direction to the true strain in the thickness direction when a sheet material is pulled in uniaxial tension beyond its elastic limit see figure 1.

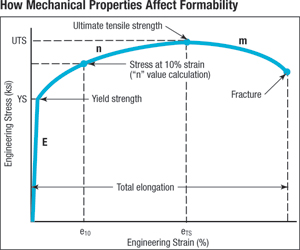

The n value describes the hardening increase in strain during plastic deformation up to uniform elongation while the r value describes the vertical anisotropism.

Simply put it measures the resistance of a material to thinning or thickening when put tension or compression.

R value also known as plastic strain ratio is a measurement of the drawability of a sheet metal.

For instance if you have a material with an r value of 12 attached to another material with an r value of 3 then both materials combined have an r value of 15.

The larger the n value the more the material can elongate before necking.

In practice the value is usually measured at 20 elongation in a tensile test.

If a material has a higher r value it is easy to avoid plane strain deformation and the material formability is higher such as mild steel.

The constant n plays a crucial role in sheet metal forming.

Less radial stretching is required with a high r value decreasing the chance of tearing failure.

The effect of the n value in deep drawing is ambiguous.

R value is a very important material property to understand for materials that will be formed into various shapes in their end use.

It is the ability to maintain thickness as the material is drawn.

The r and n values are determined in the tensile test in order to characterize the forming properties.

The r value of drawing quality steel is typically 1 and that of aluminum sheet 1 so the wrinkling problem is more severe in aluminum.

For sheet metals the r displaystyle r values are usually determined for three different directions of loading in plane 0 45 90 displaystyle 0 circ 45 circ 90 circ to the rolling direction and the normal r value is taken to be the average.